As the world increasingly seeks sustainable alternatives in various industries, construction is no exception. Among the innovative solutions, bamboo is emerging as one of the most sustainable materials available. Bamboo has been used for centuries in various parts of the world for construction, furniture, and tools. Today, with technological advancements, laminated bamboo lumber (LBL) is gaining recognition as an eco-friendly and high-performing alternative to traditional building materials such as hardwood, steel, and even concrete.

In this blog post, we will delve into the properties and performance of laminated bamboo lumber. We will begin by explaining what laminated bamboo lumber is and how it is made. Next, we will explore the key properties that make bamboo an excellent building material, comparing its performance with traditional materials. Lastly, we will discuss how LBL is used in modern construction and look into its future potential as a sustainable solution for the industry.

What is Laminated Bamboo Lumber?

Laminated bamboo lumber (LBL) is a man-made building material made by gluing together multiple layers of bamboo strips. These strips are carefully processed and bonded using adhesives to create boards or panels. The lamination process enhances bamboo’s natural strength, providing a uniform material that is both strong and aesthetically pleasing.

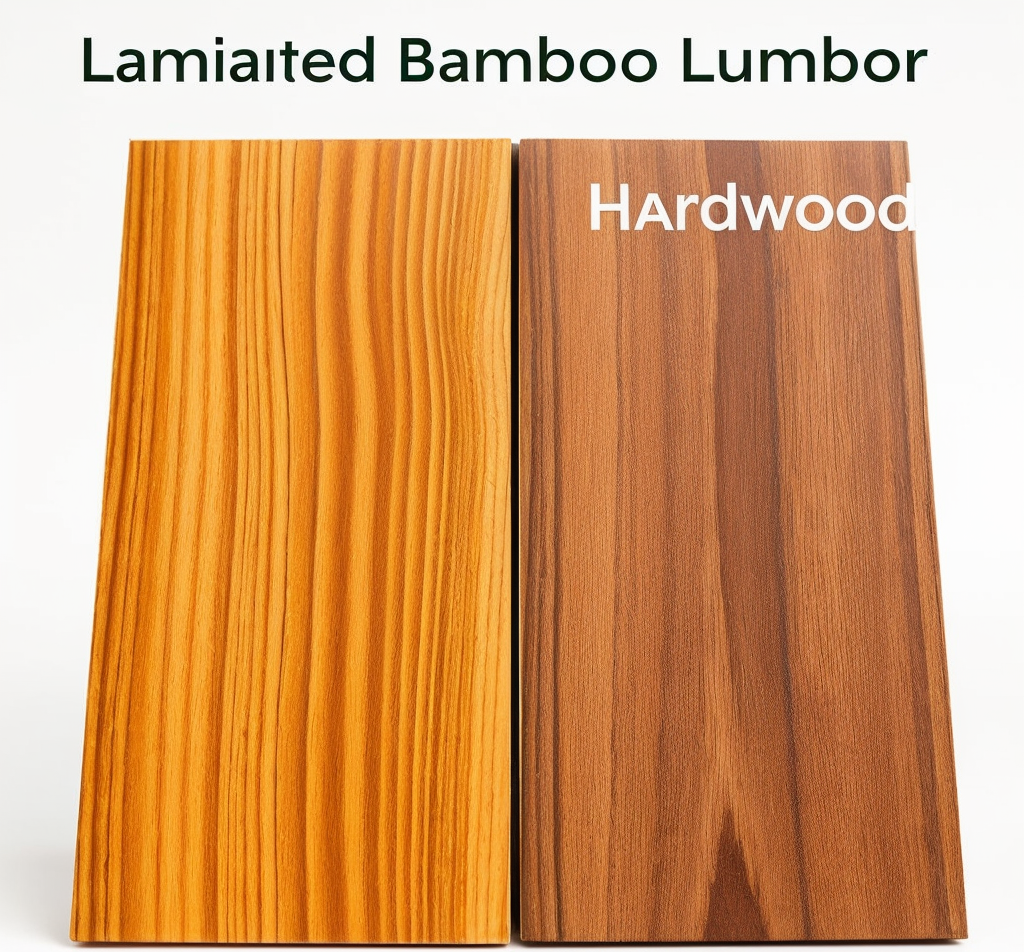

Often referred to as engineered bamboo or bamboo plywood, LBL is increasingly being used as a substitute for traditional hardwoods like oak and maple. One of its key advantages is that bamboo, being a fast-growing grass, can regenerate much faster than hardwoods, which take decades to mature. Bamboo’s sustainability makes it a standout material for environmentally conscious construction projects.

Key Properties of Laminated Bamboo Lumber

Strength and Durability

LBL is incredibly strong, often outperforming traditional hardwoods in terms of tensile strength. Bamboo fibers are naturally robust, and the lamination process enhances this strength, making LBL a suitable material for structural applications such as flooring, beams, and even furniture. Due to its high durability, LBL resists daily wear and tear, offering a long-lasting solution for builders and homeowners alike.

Moisture and Pest Resistance

One of the remarkable features of LBL is its resistance to moisture and pests. The resin-based adhesives used during the lamination process act as a barrier, protecting the bamboo from water damage and insect infestation. This makes LBL an excellent choice for both indoor and outdoor projects, such as decking, pergolas, and kitchen cabinets.

Thermal and Acoustic Insulation

Bamboo naturally provides better thermal insulation than many conventional building materials, which can help improve a building’s energy efficiency. Its density also contributes to effective acoustic insulation, reducing noise transmission. These properties make LBL a great choice for both residential and commercial projects where energy efficiency and sound control are critical.

Flexibility and Workability

Another key property of LBL is its flexibility and ease of use. Builders and contractors appreciate how easily it can be shaped, cut, and installed. This versatility allows for a wide range of applications, from structural elements to interior finishes, without sacrificing performance.

Performance of Laminated Bamboo Lumber vs. Traditional Materials

LBL vs. Hardwood

When comparing LBL to traditional hardwoods like oak and maple, LBL offers a similar level of strength and durability. However, bamboo’s faster growth rate and lower environmental impact make it a more sustainable choice. LBL is also lighter than many hardwoods, making it easier to transport and install.

LBL vs. Steel

While steel is known for its strength, bamboo offers surprising tensile strength, which allows it to be used in structural applications where steel might be considered. Although bamboo cannot fully replace steel in large-scale construction projects, it is increasingly being used in smaller structures and decorative features, providing a greener alternative.

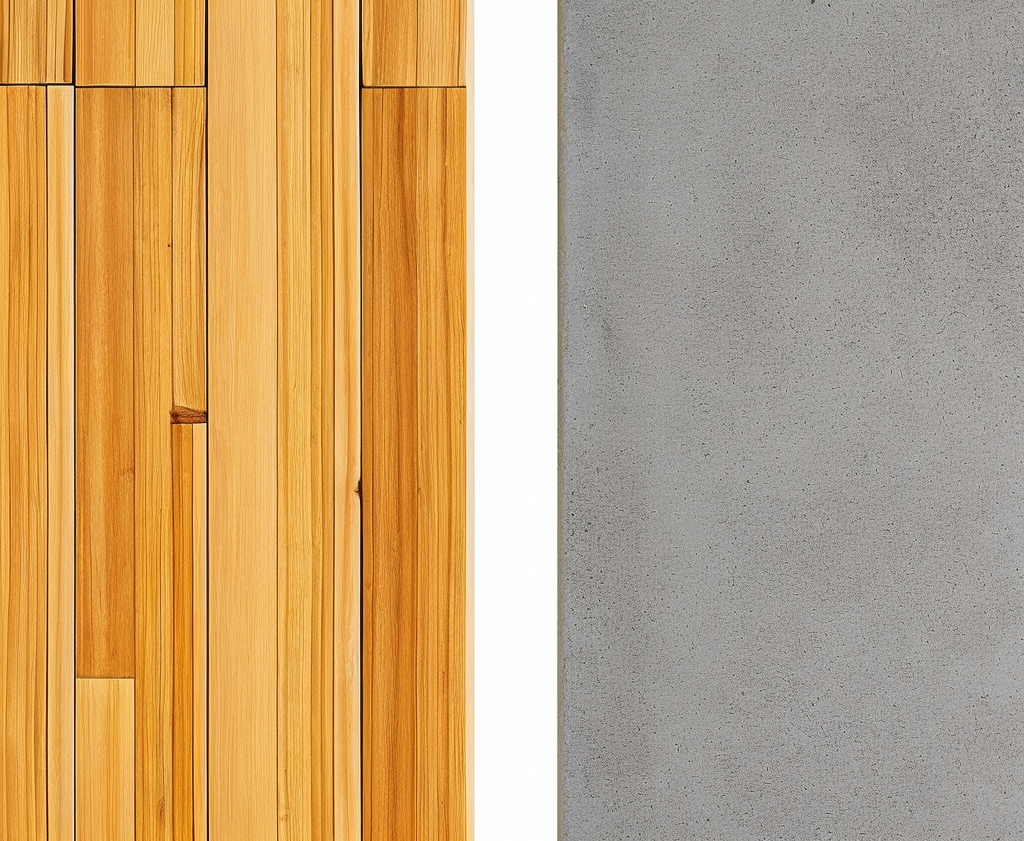

LBL vs. Concrete

Concrete, a common material in modern construction, has a much higher carbon footprint than bamboo. In some green building designs, LBL is being considered as a replacement for concrete in non-load-bearing applications. Its superior insulation properties and reduced environmental impact make it an appealing choice for energy-efficient buildings.

Sustainability Comparison

The most significant advantage of bamboo over other materials is its sustainability. Bamboo is one of the fastest-growing plants on Earth, with some species maturing in as little as three to five years. It also absorbs more carbon dioxide than trees, making it a highly renewable and eco-friendly building material.

Applications of Laminated Bamboo Lumber in Modern Construction

Residential Construction

LBL is increasingly being used in residential construction for flooring, cabinetry, and even load-bearing elements. Its strength, durability, and attractive appearance make it a preferred choice for homeowners who want an eco-friendly yet high-performing material. Bamboo’s natural beauty adds a unique aesthetic to interiors, blending sustainability with style.

Commercial Construction

In commercial settings, LBL is gaining popularity for its durability and low maintenance requirements. It is being used in office spaces, retail environments, and public buildings for furniture, wall panels, and even partitions. Bamboo’s sustainable properties and visual appeal make it a great fit for modern, green-minded companies.

Outdoor Use

Due to its moisture and pest resistance, LBL is also suitable for outdoor applications. It is often used for decking, fencing, and other landscaping features. Bamboo’s natural resilience to the elements makes it a durable option for outdoor environments, offering both function and aesthetics.

Green Building Practices

As the construction industry continues to focus on sustainability, LBL is becoming a key material in green building practices. Its rapid growth, low carbon footprint, and renewability make it an ideal material for projects aiming for certifications like LEED. Bamboo’s natural insulation properties also contribute to energy efficiency, aligning with the goals of sustainable design.

The Future of Laminated Bamboo Lumber in Sustainable Construction

With the increasing demand for sustainable building materials, laminated bamboo lumber is poised for even broader adoption. As environmental regulations become stricter and the need for renewable resources grows, LBL offers a solution that combines performance, aesthetics, and sustainability. Advances in bamboo processing technologies, such as improved adhesives and treatments, are enhancing its properties, making it more competitive with traditional materials in a wider range of applications.

In the future, we may see laminated bamboo lumber used in large-scale projects such as high-rise buildings, bridges, and infrastructure. The versatility and environmental benefits of bamboo position it as a key material for the future of construction.

Conclusion

Laminated bamboo lumber is proving to be a strong, durable, and eco-friendly alternative to traditional building materials. Its sustainability, combined with its excellent performance properties, makes it an attractive option for both residential and commercial construction. As demand for green building solutions continues to grow, bamboo is likely to play an increasingly important role in shaping the future of construction.

Consider incorporating laminated bamboo lumber into your next project to take advantage of its many benefits. At Coastal Custom Products, we are proud to offer high-quality, eco-friendly building materials that meet modern sustainability standards. Let us help you build a greener future.