The construction industry is undergoing a transformation as more and more builders, architects, and homeowners prioritize sustainability. As the global community grows increasingly aware of the environmental impact of traditional building practices, there is a strong push toward using materials that are not only durable but also eco-friendly. Sustainable building materials are at the heart of this movement, offering a way to reduce the carbon footprint of construction projects while still maintaining high standards of quality and aesthetics.

In this blog post, we will explore the lifecycle of key sustainable building materials offered by Coastal Custom Products (CCP), including laminated bamboo lumber, thermally fused laminate, PVC, and wood. From the sourcing of raw materials to the final stages of installation, we will provide an in-depth look at how these materials contribute to a more sustainable future in construction.

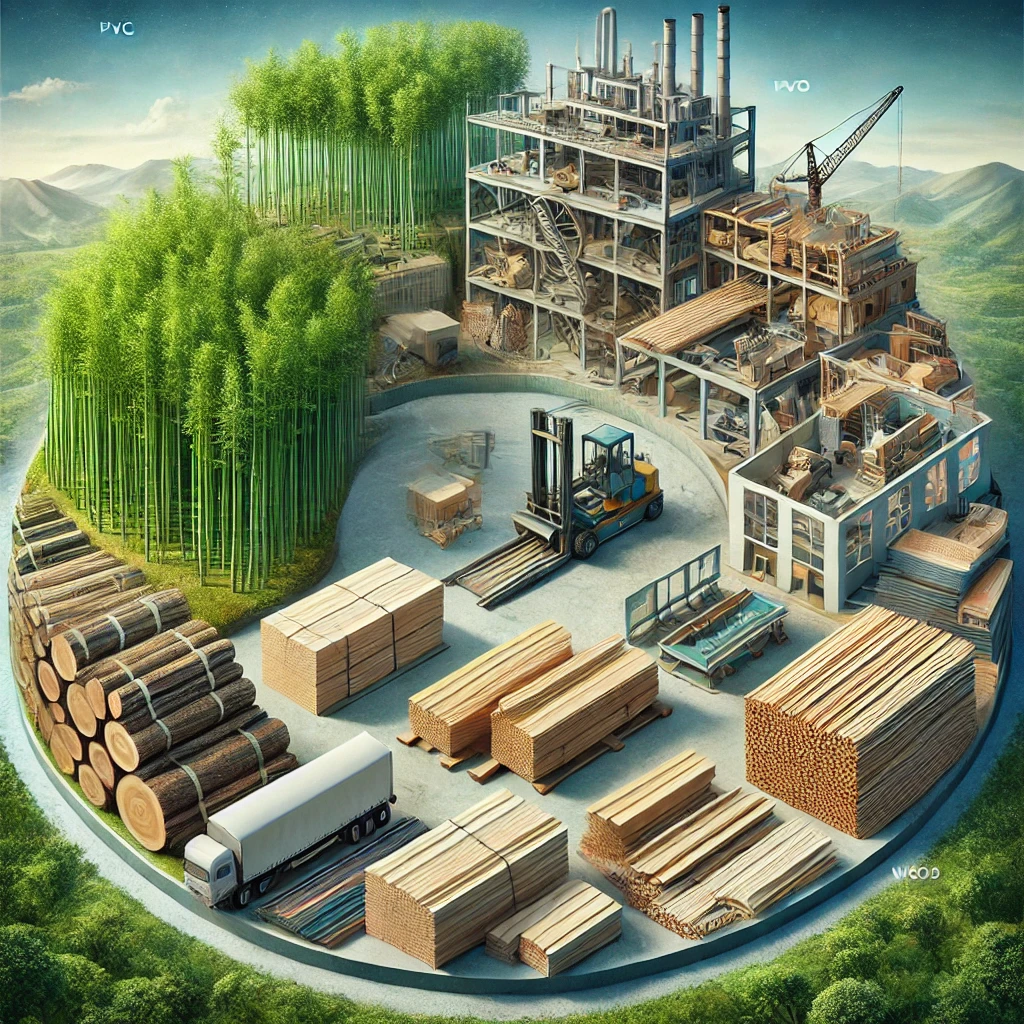

Sourcing Raw Materials

Laminated Bamboo Lumber

Bamboo is one of the most sustainable building materials available today, primarily due to its rapid growth rate. Unlike traditional hardwoods that can take decades to mature, bamboo reaches full maturity in just 3-5 years. This fast growth, combined with its natural regenerative properties, makes bamboo an incredibly renewable resource. Harvesting bamboo also requires less energy and results in minimal soil erosion, further enhancing its environmental credentials.

Thermally Fused Laminate

The wood fibers and resins used in thermally fused laminate (TFL) are sourced through responsible forestry practices. These practices include selective logging, where only certain trees are harvested, and reforestation, where new trees are planted to replace those that have been cut down. The resins used in TFL are often derived from renewable sources, reducing the reliance on petroleum-based products and minimizing environmental impact.

Polyvinyl Chloride

PVC, or polyvinyl chloride, is made from raw materials like salt and petroleum. While the extraction of these materials can have environmental impacts, advancements in the production of PVC have led to the increased use of recycled content. By incorporating recycled PVC into new products, manufacturers can significantly reduce the material’s overall environmental footprint. Additionally, the development of bio-based PVC, which uses renewable resources, is an emerging trend that further supports sustainability.

Wood

Wood remains a staple in construction, but its sustainability is heavily dependent on forestry practices. At Coastal Custom Products, we prioritize sourcing wood from manufacturers managed under strict sustainability standards. This includes practices such as selective logging, which ensures that only mature trees are harvested, and the implementation of reforestation programs. By choosing wood products from sustainably managed forests, we can ensure that this valuable resource remains available for future generations.

Manufacturing Process

Laminated Bamboo Lumber (Bamdura)

The process of turning raw bamboo into laminated lumber is both efficient and environmentally friendly. Bamboo culms are harvested and then sliced into strips, which are treated and laminated together to create strong, durable lumber. This process generates minimal waste, as even the offcuts can be used for other products. Additionally, the energy required to manufacture bamboo lumber is significantly lower compared to traditional wood products, further reducing its environmental impact.

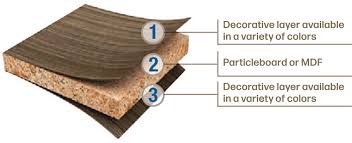

Thermally-fused Laminate (Braspan)

TFL is produced by fusing a layer of decorative paper with resin-impregnated wood fibers under high heat and pressure. This process not only creates a durable, aesthetically pleasing surface but also makes efficient use of resources. The manufacturing process is designed to minimize waste, with any leftover materials being recycled or repurposed. The durability of TFL means that it has a long lifespan, reducing the need for frequent replacements and conserving resources over time.

Polyvinyl Chloride (BOTO Plastics)

The production of PVC involves the extrusion and molding of the material into various forms, such as boards, sheets, and trim. Innovations in PVC manufacturing have focused on reducing energy consumption and emissions, making the process more eco-friendly. For instance, modern PVC production often incorporates closed-loop systems that recycle water and capture emissions, preventing them from being released into the environment. As a result, PVC products are now more sustainable than ever before.

Wood (Heywood Vloeren and Florian)

The journey of wood from forest to finished product involves several stages, including milling, kiln drying, and finishing. Each of these stages has been optimized to reduce waste and energy use. For example, sawdust and wood chips generated during milling are often used as fuel for kilns or as raw materials for other products. Additionally, advancements in kiln drying technology have made it possible to reduce energy consumption while still producing high-quality wood products.

Transportation and Distribution

Eco-Friendly Shipping

At Coastal Custom Products, we partner withthe above mentioned manufacturers in their respective countries to source our building materials. Once these materials are produced, they are imported into North Carolina, where we take extra care to ensure that the transportation process is as eco-friendly as possible. This includes optimizing shipping routes to minimize fuel consumption and reduce the carbon footprint associated with long-distance transportation. By collaborating closely with our logistics partners, we ensure that our materials arrive safely and efficiently, aligning with our commitment to environmental stewardship.

Packaging Innovations

At Coastal Custom Products, we prioritize efficiency in our shipping practices. Instead of using packaging materials, we ship our products in bundles to minimize waste. We also ensure that our containers are packed to full capacity, maximizing space and reducing the number of shipments needed. This approach not only conserves resources but also helps lower the overall environmental impact of our transportation process.

Installation and Use

Ease of Installation

One of the key benefits of using materials from Coastal Custom Products is that they are designed for ease of installation. This not only reduces the time and labor required for construction but also indirectly benefits the environment. Faster installation means fewer resources are consumed, and less waste is generated on the job site. Our materials are also designed to be compatible with a wide range of construction methods, making them a versatile choice for builders and contractors.

Performance and Longevity

The durability of Coastal Custom Products’ materials ensures that they have a long lifespan, which is a critical factor in sustainability. Materials that last longer reduce the need for frequent replacements, conserving resources and reducing waste. For example, laminated bamboo lumber is known for its strength and resistance to weathering, making it an ideal choice for outdoor applications. Similarly, thermally fused laminate and PVC products are highly resistant to moisture and wear, ensuring that they remain in good condition for many years.

Conclusion

The lifecycle of sustainable building materials from Coastal Custom Products demonstrates the potential for combining quality with environmental responsibility. By choosing materials like laminated bamboo lumber, thermally fused laminate, PVC, and wood, builders and architects can create structures that are not only aesthetically pleasing and durable but also mindful of the environment. Each stage of the lifecycle, from raw material sourcing to manufacturing, transportation, installation, and end-of-life recycling, reflects our commitment to reducing environmental impact and promoting sustainability in the construction industry.

We encourage you to consider incorporating these materials into your next project. By doing so, you’re not just choosing high-quality building products; you’re also making a choice that supports a healthier planet. Join us at Coastal Custom Products in building a greener tomorrow, one project at a time.