As the world increasingly turns its focus toward sustainability, the building and construction industry is also undergoing a significant transformation. Traditional building materials like concrete and hardwood are being reevaluated for their environmental impact, paving the way for eco-friendly alternatives. One such alternative that has gained considerable attention is bamboo lumber. Renowned for its rapid growth rate, durability, and minimal environmental footprint, bamboo is emerging as a cornerstone of sustainable construction.

In this blog post, we will explore the journey of bamboo lumber from its origins in the forest to its final application in various construction projects. We will delve into the characteristics that make bamboo a sustainable resource, the intricate process of transforming raw bamboo into laminated lumber, and the versatile applications of this remarkable material. Additionally, we will highlight the commitment of Coastal Custom Products to sustainable practices and the broader environmental benefits of using bamboo lumber. Join us as we uncover the fascinating and eco-friendly journey of bamboo lumber production.

Understanding Bamboo as a Sustainable Resource

Bamboo’s reputation as a sustainable resource is well-earned, primarily due to its rapid growth and regenerative properties. Unlike traditional timber, which can take decades to mature, bamboo reaches maturity in just three to five years. This fast growth cycle allows for frequent harvesting without depleting the resource. Additionally, bamboo does not require replanting after harvesting, as it regenerates from its root system, making it a highly renewable resource.

Growth and Harvesting

Bamboo is a type of grass, and its growth characteristics set it apart from traditional hardwoods. It can grow up to 35 inches per day in optimal conditions, making it one of the fastest-growing plants on Earth. Harvesting bamboo involves cutting the mature poles at ground level, which then regrow from the same root system. This method not only ensures a continuous supply but also prevents soil erosion and promotes soil health.

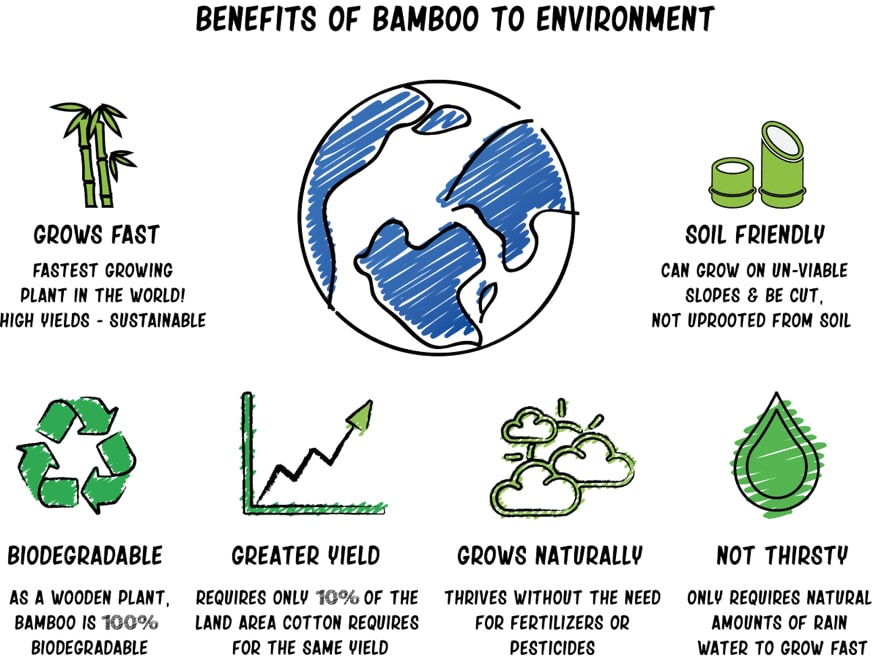

Environmental Benefits

Bamboo plays a crucial role in carbon sequestration, absorbing more CO2 and releasing more oxygen than an equivalent stand of trees. This makes bamboo cultivation an effective tool in combating climate change. Furthermore, bamboo's extensive root system stabilizes the soil, reduces erosion, and improves water retention, contributing to healthier ecosystems. Its low water and pesticide requirements also make it an environmentally friendly crop.

The Process of Bamboo Lumber Production

Transforming raw bamboo into high-quality laminated bamboo lumber involves several meticulous steps, each designed to preserve the material’s integrity and enhance its durability. The process is a blend of traditional techniques and modern technology, ensuring that the final product meets rigorous standards of quality and sustainability.

Harvesting and Initial Treatment

After harvesting, bamboo poles are subjected to a treatment process to prevent pest infestation and decay. This typically involves soaking the bamboo in a borate solution, which acts as a natural preservative. The treated poles are then left to dry, reducing their moisture content and preparing them for further processing.

Splitting and Stripping

The dried bamboo poles are split into smaller strips, a process that involves cutting the poles lengthwise. These strips are then stripped of their outer layer and nodes to create uniform pieces. This step is crucial for ensuring consistency in the final product.

Boiling and Drying

The bamboo strips are boiled to remove any remaining starch, which could attract pests. Boiling also helps in removing natural sugars that could lead to mold growth. After boiling, the strips are thoroughly dried, reducing their moisture content to optimal levels for lamination.

Lamination and Pressing

The dried bamboo strips are then glued together in layers, with the grains running in opposite directions to enhance strength and stability. These layers are pressed together under high pressure and heat to form solid, laminated panels. This process not only enhances the structural integrity of the bamboo but also makes it more resistant to warping and cracking.

Finishing and Quality Control

The laminated bamboo panels undergo a series of finishing processes, including sanding and cutting to precise dimensions. Each panel is inspected for quality, ensuring it meets the stringent standards required for construction and interior design applications. Any defective pieces are recycled or repurposed, minimizing waste.

Applications and Benefits of Bamboo Lumber

Bamboo lumber is incredibly versatile and can be used in a wide range of construction and interior design applications. Its strength, durability, and aesthetic appeal make it an excellent alternative to traditional building materials.

Applications in Construction

Bamboo lumber is commonly used for flooring, paneling, and structural components. Its natural beauty and unique grain patterns make it a popular choice for both residential and commercial projects. In addition to flooring, bamboo is used in cabinetry, furniture, and decorative elements, offering a stylish and sustainable option for various design needs.

Benefits for Builders and Homeowners

Bamboo lumber offers numerous benefits over traditional materials. It is not only durable and resistant to wear and tear but also cost-effective, often providing a more affordable option without compromising on quality. Additionally, bamboo's natural aesthetic adds a warm and modern touch to any space. From an environmental perspective, using bamboo lumber significantly reduces the carbon footprint of a construction project, supporting a more sustainable building industry.

Coastal Custom Products' Commitment to Sustainability

At Coastal Custom Products, sustainability is at the core of everything we do. We are committed to ensuring that our bamboo lumber production processes are as eco-friendly as possible. Our bamboo is sourced from responsibly managed plantations that adhere to strict environmental standards. We employ energy-efficient technologies in our production facilities, reducing our overall carbon footprint.

Conclusion

The journey of bamboo lumber from forest to floor is a testament to the possibilities of sustainable building materials. Bamboo’s rapid growth, environmental benefits, and versatility make it an ideal choice for modern construction needs. Coastal Custom Products is proud to be a part of this green revolution, providing high-quality bamboo lumber that meets the demands of eco-conscious builders and homeowners alike. As we continue to explore and innovate, we invite you to join us in embracing a more sustainable future.

Discover more about our eco-friendly bamboo lumber and other sustainable building materials by visiting the Coastal Custom Products website. For inquiries and detailed product information, feel free to contact us. Stay updated on our latest products and sustainability efforts by following us on social media.